Shipping calculated at checkout

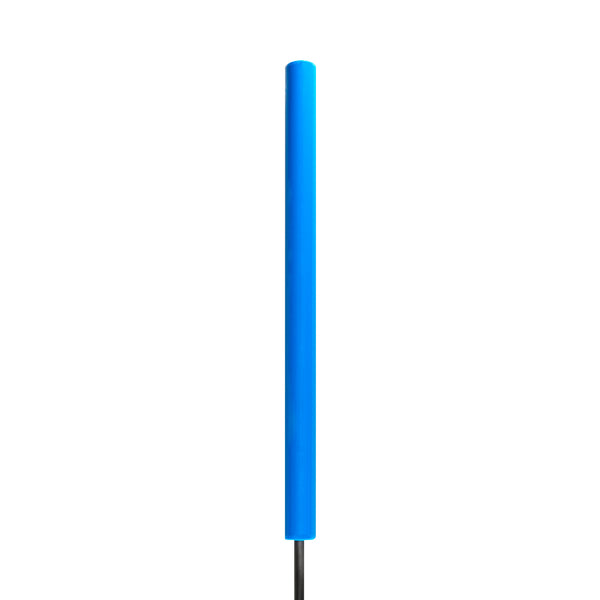

Sliding Ground Rod

The integrated Sliding Ground Rod simplifies putting a ground rod into difficult soils. It is self-contained, easy to use, carry and store. The handle slides up and down on the single piece ground rod shaft, driving it into or out of the ground. Electronic locating equipment can connect to the shaft allowing the shaft to work as a grounding device.

The sliding handle has been specifically designed to reduce the risk of injury by minimizing the number of pinch points.

All internal pieces of the head assembly are manufactured from high strength, impact resistant tool steel. This steel is designed for minimum distortion, ensuring a long lasting tool.

The Sliding Ground Rod can be ordered powder coated or plastisol dipped for comfort.

FEATURES:

Handle:

- Sturdy 1.5” diameter steel tube

- 21-inch overall length

- 16-inch stroke to provide an optimal distance for driving the rod into the ground while reducing weight

Shaft:

- Shaft is used as a grounding rod

- 1/2-inch rod diameter

- 26-inch usable length

- High-quality alloy steel resists bending and bowing

- Single piece shaft integrated into handle

- Specially designed to minimize pinch points

CAUTION!

This tool is NOT INSULATED and DOES NOT provide protection against electrical shock.